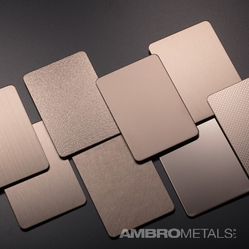

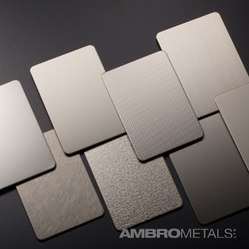

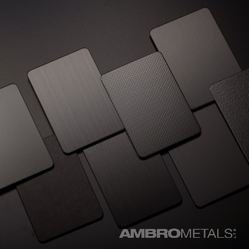

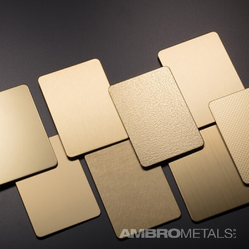

PVD & ELECTRO Interior Stainless Steel Finishes

Electro Coating is a process where the metal substrate (Stainless Steel sheet), is immersed into a solution which acts as the medium to allow an anode metal to sacrifice or transfer to a cathode metal. The process uses electrolysis to positively charge the conductive anode which is then collected by the cathode. The rate and thickness in which this is created is determined by the amount of electrical current introduced.

Advantages of Electrocoating

Physical Vapour Deposition (PVD) is a process to produce a metal vapour (titanium, chromium and aluminium) that can be deposited on electrically conductive materials as a thin highly adhered pure metal or alloy coating. The process is carried out in a vacuum chamber using a cathodic arc source.

The coating compounds are made up of various elements such as carbides, nitrides, borides and silicides. The different colours are achieved by adding different gasses during the deposition.

Why choose Coating?

RECENTLY COMPLETED

14 Timothy Place,

Avondale, Auckland 1026

New Zealand

Questions?

Call us at 0800 484 111 or leave us a message:

14 Timothy Place,

Avondale, Auckland 1026

New Zealand

Questions?

Call us at 0800 484 111 or leave us a message: